Why is epoxy-coated steel used in construction ?

Epoxy coated TMT bar, one of the best TMT bars in India, are a highly corrosion resistant variant of steel bars which are protected by Fusion Bonded Epoxy (FBE) coating. Fusion Bonded Epoxy coating, commonly referred to as FBE coating is widely used to protect concrete TMT bars, steel pipes, piping connections etc. used in construction.

FBE coatings are in the form of dry powder at normal atmospheric temperature. The powder is applied electrostatically to the surface of cleaned hot steel bars and cured to form a protective film after undergoing various chemical processes. The epoxy coated bars last longer due to the protective film and thereby contribute to the quality of construction.

Epoxy coated rebar is a viable option and I think overall, it will provide you with significant protection from corrosion based on much history and testing. But knowing that the quality of the protection is based on the condition/quality of the epoxy coating on the bar itself is very important.

Advantages of Epoxy Coated bars:

Economical

The superior corrosion protection can extend the life of the epoxy coated TMT bars, resulting in significantly lower lifecycle costs over time.

Requires Less Maintenance

It needs little maintenance that leads to substantial savings in labour costs. It is flexible to allow straight bars to be bent during fabrication on a special mandrel to protect the coating from damage.

Environment-friendly

Epoxy powder coated bar is a sustainable solution that is environment friendly.

Long lasting

Studies have shown that structures built with epoxy last longer than similar structures made with black steel.

Cost-effective

Epoxy coating is very cost-effective as it adds very little to the overall cost of the structure and lifecycle.

Superior Quality

As the technique is factory based, it enables uniform thickness of coating which adds to the quality of production.

Excellent Bonding

The bonding of coating with steel TMT bars is high as it has excellent adhesive property.

Offers Barrier Protection

The Fusion Bonded Epoxy coating acts as an insulator for electrochemical cells and offers barrier protection to steel which prevents entry of chloride ions through it.

Process of manufacturing Epoxy TMT Steel Bars:

Surface Preparation

TMT bar is cleaned for surface contamination such as grease and oil by solvent cleaning. Shot blast cleaning is the most commonly used method for preparation of steel surfaces. This effectively removes rust, scales, slats etc. from the surface and produces an industrial grade of a clean and rough surface finish.

Pre-Heating

Heating can be achieved by using several methods, but the most efficient method is induction heating. TMT bars are passed through a high frequency alternating current along with a magnetic field, which heats according to the required FBE coating application temperature. Typical application temperature for a stand-alone FBE is 225°C to 245°C.

Epoxy Powder Application

The FBE powder is placed on a fluidisation bed. The heated TMT bar is passed through the coating booth with number of electrostatic epoxy spray guns and the dry powder is sprayed (cloud formation) on the hot TMT bar. Here, the powder particles are suspended in a stream of air which is electrically charged due to which epoxy powder particles are attracted to the grounded TMT bar. As soon as the charged epoxy powder particles hit the hot TMT bar, they melt and flow into the anchor profile. The heat also initiates a chemical reaction which causes the epoxy powder molecules to form cross linked polymers which give the coating its beneficial properties.

Curing and Cooling

Epoxy coated TMT bars are given a thermal treatment by keeping them at 225°C for a duration recommended by epoxy powder manufacturer resulting in fully cured coating. The coated bars are passed through a cooling tunnel after curing, where water is sprayed on the bars to cool them. The bars are then transferred to the final inspection rack for testing and inspection.

Manufacturing of Epoxy Coated Rebar

The manufacturing process of Epoxy Coated Rebars involves 4 important steps, surface preparation, induction preheating, fusion with epoxy powder application and curing. Coating operation involves moving the straight length of steel through the application process on a rapidly moving conveyor. Specialized coating operation units may use a special hanger system. The steps are as followed;

- The process starts with rebars positioned into shakeout table or fluidization bed where it is spread out to a conveyor system

- The steel is visually inspected for oil, grease and other contaminants

- The steel is then moved towards a blast cleaner wherein the contaminants are removed

- The steel is now ready for proper coating

- Bars them pass through a powder spray booth where spray nozzles embed a dry epoxy powder

- Electrostatic charges are then pushed into the powder particles resulting incomplete and even coating

- As dry powder heats the hot steel it melts and flows into the peaks and valleys of the steel covering and conforming to the bars

- Following the powder application, the coating is allowed to cool for 30- 40 seconds

- The coating cures to a hardened state and develops most of its beneficial properties

- Air or water quench often follows the curing period to cool off the bar and facilitate handling

- The coated bars are passed through a cooling tunnel after curing, where water is sprayed on the bars to cool them

- The bars are then transferred to the final inspection rack for testing and inspection.

Different test methods for checking the quality of Epoxy Coated Rebar

Apart from the manufacturing process, there are several test methods to confirm the quality of the Epoxy Coated TMT Bar, which are given below.

- Test Method for holiday detection

- Test Method for coating thickness

- Test Method for impact strength

- Test Method for bendability

- Test Method for bond strength

- Test Method for alkali resistance

- Test Method for corrosion resistance

Advantages of Epoxy Coated Rebar

Plain steel often falls prey to corrosive forces over time. As rust forms on the outside of the embedded rebar, it exerts an increasing amount of pressure on the surrounding concrete. This can cause the concrete slab to spontaneously crack, while also making the concrete more vulnerable to damage caused by blows and compressive forces. The surface of the concrete may develop patches of spalling, creating rough and unattractive areas. Epoxy-coated rebar prevents corrosion and the problems that it causes and offers a multitude of advantages.

- The coating layer is firm and stable which offers good tenacity and high insulation

- The coating layer is corrosion-resistant

- Lower maintenance cost

- Lower lifecycle costs over time

- Uniform thickness of coating which adds to the quality of production

- Acts as an insulator for electrochemical cells and offers barrier protection to steel which prevents the entry of chloride ions

- Excellent adhesion and it forms a lasting bond with the surface of the steel rebars

- High mechanical impact strength.

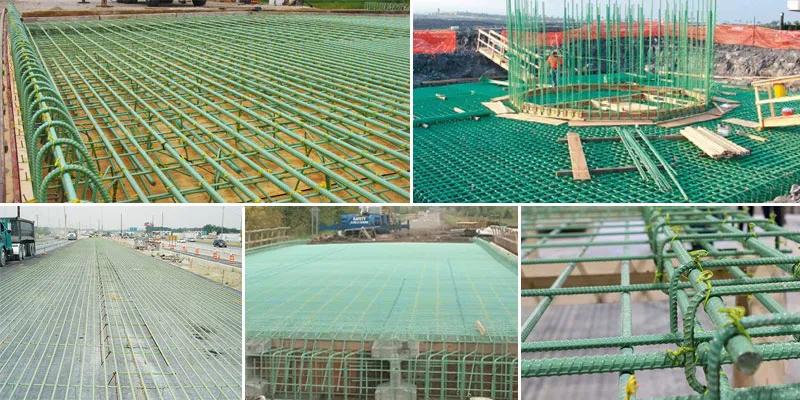

Applications of Epoxy Coated Rebar

Epoxy Coated TMT Rebars are used in concrete subjected to corrosive conditions. These may include exposure to deicing salts or marine environments.

- Underground buildings

- Bridges

- Pavements

- Offshore structures.

- Parking structures.

- Marine structures