Quality Engineer Should know these points

Cement :-

- Cement delivered hot from the factory shall not be used at temperature in excess of about 77ºC.

- No cement shall be kept on the site longer than three months before use.

- Any cement which is stored on site in excess of 90 days shall be tested in accordance with relevant Standard prior to use.

- The store temperature shall not exceed 40ºC.

- Sufficient cement for one week’s consumption shall be available at all times. Cement shall be used in the sequence in which it is delivered.

- The following cement types shall be used.

- Grade 43 Ordinary Portland Cement (OPC) conforming to IS 8112.

- Grade 53 Ordinary Portland Cement (OPC) conforming to IS 12269.

- OPC 53 grade with C3A content from 5% to 8%.

- Factory blended Portland Pozzolana Cement (PPC) containing fly ash grade 1 conforming to IS 1489 with fly ash content more than 26%.

- Rapid Hardening Portland Cement to IS 8041.

- Sulphate Resisting Cement to IS 12330.

- Portland Slag cement with slag content more than 50% conforming to IS 455. (Ground Granulated Blast Furnace Slag (GGBS) can be used conforming to IS 12089)

Water :-

- Water used for the following purpose shall be free of injurious amount of oil, acids, alkalies, salts, sugar,

- The pH value of water shall be not less than 6.

- Limits for Solids in Water shall not exceed as given below

| Item | Maximum Limit |

| Organic | 200 mg/l |

| Inorganic | 3000 mg/l |

| Sulphates (as SO3) | 400 mg/l |

| Chlorides (as Cl) for plain concrete | 2000 mg/l |

| Chlorides (as Cl) for RCC | 500 mg/l |

| Suspended Matter | 2000 mg/l |

The maximum concentrations in water shall not exceed the following :-

- Shall not exceed more than 5 ml of 0.02 normal NaOH, using phenolphthalein, to neutralize 100 ml sample of water

- Shall not exceed more than 25 ml of 0.02 normal H2SO4, using mixed indicator, to neutralize 100ml sample of water

MAXIMUM WATER CEMENT RATIO

| EXPOSURE | PLAIN CONCRETE | REINFORCED CONCRETE |

| Mild – For Example, completely protected against weather, or aggressive conditions, except for a brief period of exposure to normal conditions during construction | 0.6 | 0.55 |

| Moderate – For example, sheltered from heavy and wind driven rain and against freezing, whilst saturated with water; buried concrete in soil and concrete continuously under water | 0.6 | 0.50 |

| Severe – For Example, exposed to sea water, alternate wetting and drying and to freezing while wet, subject to heavy condensation or corrosive fumes. | 0.5 | 0.45 |

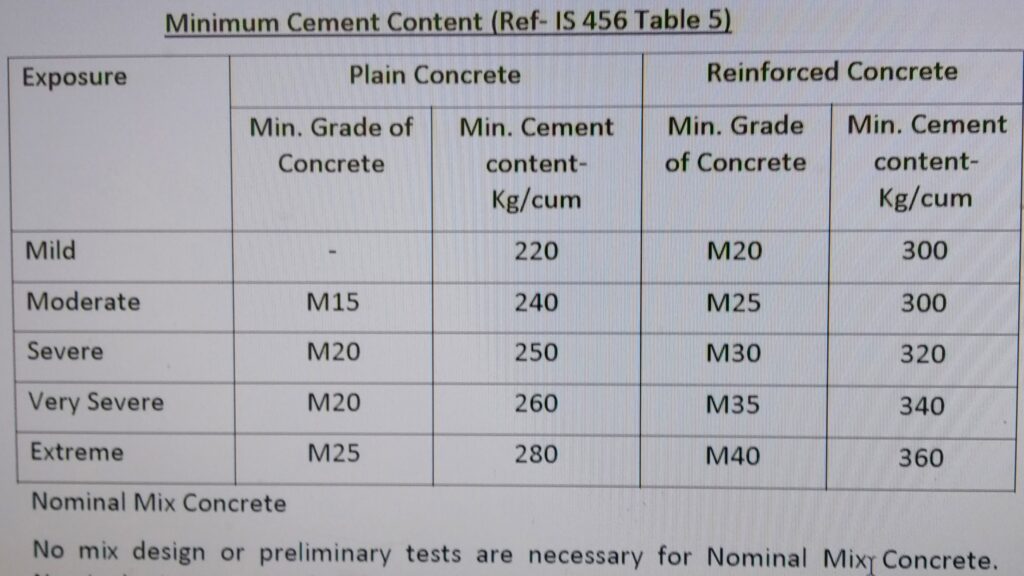

Minimum Cement ContentAS per 456

Plum concrete :-

Stone aggregates of size up to 0.001 m3, but less than 1/3 of the least dimension to be concreted, called plums, shall be used as aggregate. These plums shall be subject to the same acceptability tests which are applicable to the normal aggregates.

The volume of plums shall not exceed 20% of the total volume of the finished concrete, and they shall be well dispersed throughout the mass. This shall be achieved by placing a layer of normal concrete, then spreading the plums, followed by another layer of concrete around the plum. Care must be taken to ensure that no air is trapped underneath the stones and that the concrete does not work away from their underside. The plums must have no adhesive coating.

Initial Setting Time :-

The initial setting time shall be not less than 30 min after the produced concrete is discharged into the forms and with a maximum time between mixing and completion of placing concrete shall not exceed 1 hour, the total time between mixing and initial set shall be a minimum of 1 hour. There shall be a maximum setting time of 6 hours.

Slump :-

The slump of the structural concrete mixes shall be such that the concrete can be transported, placed into the forms, and compacted without segregation that a super plasticiser is not used in the mix

The permissible slump should be 75 + 25mm as measured in accordance with IS 1199. Slump for pump-able concrete shall be determined by site trials and 100 + 25mm on site of pouring.

Placing Concrete With the Tidal Range :-

When concreting is to be carried out under tidal conditions the CONTRACTOR shall ensure that concrete is placed and compacted before the sea water rises to the level of the concrete so placed.

No concrete shall be disturbed after salt water has made contact with it. The top surface of the concrete shall be covered after the initial set has taken place, to protect it against water action if there is any risk of this occurring.

The CONTRACTOR shall submit to the CONSTRUCTION MANAGER for approval details of the proposed method for complying with these requirements.

Placing Concrete Underwater :-

Underwater concreting shall be permitted only with the approval of the CONSTRUCTION MANAGER.

Concrete placed underwater may be lowered in bottom opening skips or may be fed continuously through an approved remit pipe or pipes provided with suitable hoppers.

The positions and level of the remit pipes shall be readily adjustable, and the pipes shall be of sufficient bore and have their ends firmly fixed.

Unless otherwise agreed with the construction manager, the cement content of any concrete mix to be placed underwater shall be increased by 20%.

Curing :-

Curing shall be continued for at least seven days from the date of placing concrete in case of OPC.

The period of curing shall not be less than 10 days for concrete exposed to dry and hot weather conditions.

Curing compounds

Curing compounds shall conform to India standards and shall be applied in accordance with the manufacturer’s instructions to provide a water loss not greater than 0.55 kg/m2 in 72 hours.

Mass Concreting (Critical Large Foundations)

The heat of hydration during concreting shall be controlled by using methods to prevent high-temperature differential between the interior of the concrete and any outside face.

The heat of hydration shall not cause a temperature differential greater than 20°C for thicknesses up to 1 m or 15°C for thicknesses over 1 m.

Recommended remedial measures for controlling the temperature of concrete:

- Methods to precool concrete include shading and sprinkling the aggregate piles, use of chilled mixing water and replacing a portion of mix water with flaked ice.

- The form work and the top surface of the structure must be adequately insulated with polystyrene or urethane. Additional insulation is needed at edges and corners.

- After the concrete has been placed, its peak temperature in any part of the concrete mass shall not rise above 70˚C.

- Insulating Surface by use of 25mm thick expanded synthetic material, such as polystyrene or polyurethane or 50mm thick high density thermocole. The curing shall not be done by spraying or ponding of water as these have rapid cooling effect.

- The risk of early thermal cracking may be minimized through use of concrete mixtures with low coefficient of thermal expansion, crush

- Reducing the temperature by using low content of cement with high proportion of Pozzolana. The usage of super plasticizers to prevent potential cold joints.

- Use aggregates higher than 20mm size, if reinforcement and piping embedment’s permits.

- It is recommended that concreting begin early evening (say 4pm) and continue through the late evening / night and (if required) into early morning