Anti-termite treatment in new Construction ?

Anti-termite treatment is a chemical process carried out for soil, masonry, wood, to provide the building with a chemical barrier against the termites before and after construction.

In other-words , application of chemicals (toxic ant) to the soil adjacent to and under a building to form a chemical barrier which is lethal or repellent to termites.

Anti-termite treatment is done at two stages :-

- Pre – construction anti-termite treatment

- Post construction anti-termite treatment

Pre – construction anti-termite treatment

The chemicals used for anti-termite treatment in buildings as per Indian Standards (IS 6313 Part-3) are :

- Chlorpyrifos 20 EC

- Lindane 20 EC

This treatment takes place before the construction completes. In this anti-termite treatment, the soil, building pillars and other joints are treated with chemicals to prevent termites.

| Mix 1 Litre of Piramid (Chlorpyriphos 20% EC) with 19 litres of water to get a 1% ai Piramid Emulsion and apply of the below stages. |

| Check that Plinth filling holes up to 500 mm deep and 150 mm centers shall be made along the all beams and columns. The chemical Emulsion shall be poured/sprayed @7.5Ltr/Sqmts of the vertical surface into these holes. |

| Check that the top surface of consolidated earth in plinth area new soil level below ground floor slab shall be treated with chemical emulsion @ 5.0 Ltr / Sqmts.( diluted liquid) |

Note :- It is so less expensive as compared to Post Anti – termite

Post construction anti-termite treatment

This treatment is done after the construction is complete. In this treatment mostly the drill, fill and seal method is followed.

In this method a hole is drilled in the termite infested area, it is then filled with termiticide and finally, it is sealed causing a barrier for the termite and cutting out all supply from it.

Treatment along outside of foundations :-

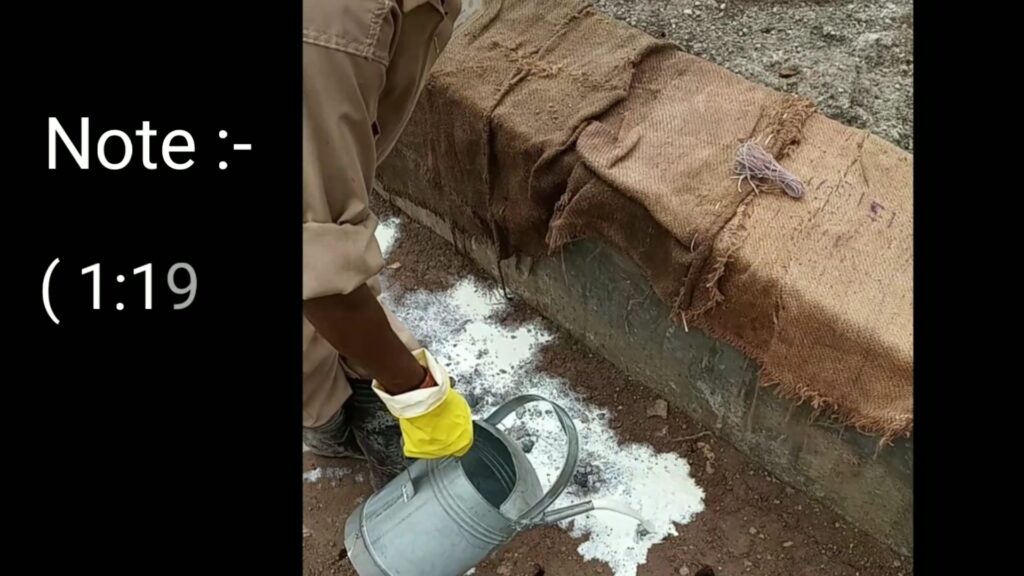

The soil in contact with the external wall of the building shall be treated with chemical emulsion at the rate of 7.5 l/m2 of the vertical surface of the substructure to a depth of 300 mm.

To facilitate this treatment a shallow channel shall be excavated along and close to the wall at 1.75 Iitres per running metre of the channel. Rodding with 12 mm diameter mild steel rods at 150mm apart shall be done in the channel if necessary for uniform dispersal of the chemical to 300 mm depth from the ground level.

The balance chemical of 0.5 litre per running metre shall then be used to treat the backfill earth as it is returned to the channel directing the spray toward the wall surface.

If there is a concrete or masonry apron around the building, approximately 12 mm diameter holes shall be drilled as close as possible to the plinth wall at 300 mm apart, deep enough to reach the soil below, and the chemical emulsion pumped into these holes to sodk the soil below at a rate of 2.25 Iitres per linear metre

Treatment to voids in masonry :-

Termites are known to seek entry into masonry foundations and work their way up through voids in the masonry and enter the building at ground and upper floors.

The holes shall be drilled at a downward angle of about 45° preferably from both sides of the plinth wall at approximately 300 mm intervals and emulsion squirted through these holes to soak the masonry using a hand operated pressure pump. This treatment shall also be extended to internal walls having foundations in the soil.