Rebound Hammer Test on Concrete – Procedure & Basic

What is Rebound Hammer Test

Rebound Hammer test is a Non-destructive testing method of concrete which provide a convenient and rapid indication of the compressive strength of the concrete. Rebound hammer test method is based on the principle that the rebound of an elastic mass depends on the hardness of the concrete surface against which the mass strikes.

The rebound hammer is also called as Schmidt hammer that consist of a spring controlled mass that slides on a plunger within a tubular housing.

OBJECT OF TEST

As per the Indian code IS: 13311(2)-1992, the rebound hammer test have the following objectives:

i) Assessing the likely compressive strength of concrete with the help of suitable correlations between rebound index and compressive strength

ii) Assessing the uniformity of concrete

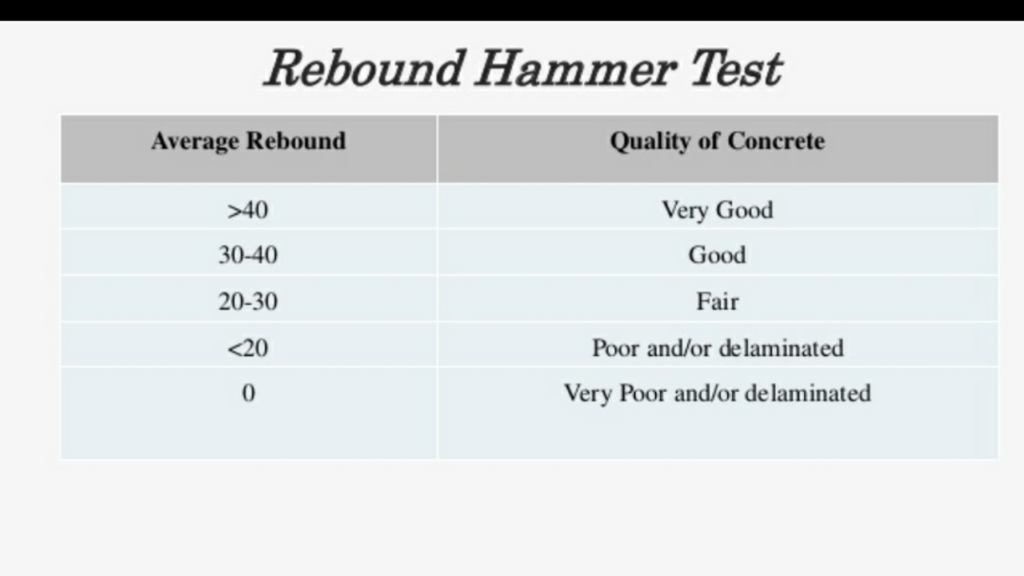

iii) Assessing the quality of the concrete in relation to standard requirements

iv) Assessing the quality of one element of concrete in relation to another.

NOTE – The rebound hammer method can be used with greater confidence for differentiating between the questionable and acceptable parts of a structure or for relative comparison between two different structures.

Principle of Rebound Hammer Test

This Method is based on the principle that the rebound of an elastic mass depends on the hardness of the concrete surface against which the mass strikes. When the plunger of rebound hammer is pressed against the concrete surface, the spring controlled mass in the hammer rebounds. The amount of rebound of the mass depends on the hardness of concrete surface.

The compressive strength can be read directly from the graph provided on the body of the hammer.

Procedure

The test thus can be conducted horizontally on vertical surface and vertically upwards or downwards on horizontal surfaces .

- For testing, smooth, clean and dry surface is to be selected. If loosely adhering scale is present, this should be rubbed of with a grinding wheel or stone. Rough surfaces resulting from incomplete compaction, loss of grout, spalled or tooled surfaces do not give reliable results and should be avoided.

- The point of impact should be at least 20 mm away from any edge or shape discontinuity.

- For taking a measurement, the rebound hammer should be held at right angles to the surface of the concrete member. The test can -thus be conducted horizontally on vertical surfaces or vertically upwards or downwards on horizontal surfaces. If the situation demands, the rebound hammer can be held at intermediate angles also, but in each case, the rebound

- Rebound hammer test is conducted around all the points of observation on all accessible faces of the structural element.

APPARATUS

It consists of a spring controlled mass that slides on a plunger within a tubular housing.

It is necessary that the rebound hammer is checked against the testing anvil before commencement of a test to ensure reliable results. The testing anvil should be of steel having Brinell hardness of about 5 000 N/ms. The supplier/manufacturer of the rebound hammer should indicate the range of readings on the anvil suitable for different types of rebound hammers.

Impact Energy for Rebound Hammers for Different Applications

| Applications | Approximate Impact Energy for Rebound Hammer in Nm | |

| 1 | For Normal Weight Concrete | 2.25 |

| 2 | For light weight concrete / For small and impact resistive concrete parts | 0.75 |

| 3 | For mass concrete testing Eg: In roads, hydraulic structures and pavements | 30.00 |

Correlation between compressive strength of concrete and rebound number

The most satisfactory way of establishing a correlation between compressive strength of concrete and rebound number is to test the concrete cubes using compression testing machine as well as using rebound hammer simultaneously. First the rebound number of concrete cube is taken and then the compressive strength is tested on compression testing machine. The fixed load required is of the order of 7 N/ mm2 when the impact energy of the hammer is about 2.2 Nm.

The load should be increased for calibrating rebound hammers of greater impact energy and decreased for calibrating rebound hammers of lesser impact energy. The test specimens should be as large a mass as possible in order to minimize the size effect on the test result of a full scale structure. 150mm cube specimens are preferred for calibrating rebound hammers of lower impact energy (2.2Nm), whereas for rebound hammers of higher impact energy, for example 30 Nm, the test cubes should not be smaller than 300mm.

The concrete cube specimens should be kept at room temperature for about 24 hours after taking it out from the curing pond, before testing it with the rebound hammer. To obtain a correlation between rebound numbers and strength of wet cured and wet tested cubes, it is necessary to establish a correlation between the strength of wet tested cubes and the strength of dry tested cubes on which rebound readings are taken.

A direct correlation between rebound numbers on wet cubes and the strength of wet cubes is not recommended. Only the vertical faces of the cubes as cast should be tested. At least nine readings should be taken on each of the two vertical faces accessible in the compression testing machine when using the rebound hammers. The points of impact on the specimen must not be nearer an edge than 20mm and should be not less than 20mm from each other. The same points must not be impacted more than once.

Factors Influencing Rebound Hammer Test

Below mentioned are the important factors that influence rebound hammer test:

- The rebound numbers are influenced by a number of factors like types of cement and aggregate, surface condition and moisture content, age of concrete and extent of carbonation of concrete.

- Influence of Type of Cement Concretes made with high alumina cement can give strengths 100 percent higher than that with ordinary Portland cement. Concretes made with supersulphated cement can give 50 percent lower strength than that with ordinary Portland cement.

- Influence of Type of Aggregate Different types of aggregate used in concrete give different correlations between compressive strength and rebound numbers. Normal aggregates such as gravels and crushed rock aggregates give similar correlations, but concrete made with lightweight aggregates require special calibration.

- Influence of Surface Condition and Moisture Content of Concrete The rebound hammer method is suitable only for close texture concrete. Open texture concrete typical of masonry blocks, honeycombed concrete or no-fines concrete are unsuitable for this test. All correlaticns assume full compactjon, as the strength of partially compacted concrete bears no unique relationship to the rebound numbers. Trowelled and floated surfaces are harder than moulded surfaces, and tend to overestimate the strength of concrete. A wet surface will give rise to underestimation of the strength of concrete calibrated under dry conditions. In structural concrete, this can be about 20 percent lower than in an equivalent dry concrete.

- Influence of Curing and Age of Concrete The relationship between hardness and strength varies as a function of time. Variations in initial rate of hardening, subsequent curing and conditions of exposure also influence the Relationship. Separate calibration curves are required for different curing regimes but the effect of age can generally be ignored for concrete between 3 days and 3 months old.

- Influence of Carbonation of Concrete Surface The influence of carbonation of concrete IS 1331.1 (Part 2 ) : I992 surface on the rebound number is very significant. Carbonated concrete gives an overestimate of strength which in extreme cases can be up to 50 percent. It is possible to establish correction factors by removing the carbonated layer and testing the concrete with the rebound hammer on the uncarbonated concrete.

I need result from graph ..can you help me

ofcourse message me on my whatsapp

Kamagra Original Erkennen Skingmok [url=https://biracialism.com/]soft tab cialis[/url] Speern Comprar Levitra En Andorra Sin Receta Glulse Cialis ornanceunada Kamagra Prescription