Why Foundation in Black Cotton Soil is a Risky & Which foundation is used in black cotton soil ?

Black cotton soil is very heavy clay soil , Varying from clay to loam . It is generally light to dark grey in colour. cotton grows in this kind of soil. In India about 15 % soil is cotton in all soil .

Black cotton soils and other expansive soils have typical characteristics of shrinkage and swelling due to moisture movement through them. During rainy season, moisture penetrates into these soils, due to which they swell .

In addition to this, these soils have very poor bearing capacity, ranging from 5 T/m 2 to 10 T/m 2. If there is a chance for water to come in contact with foundation, then the load should be limited to 4.9 tonnes/m2.

So, Building a foundation in black cotton soil is so risky .The swelling and shrinkage of expansive soil cause the settlement of building. When dry, it is very hard, but it loses strength completely when wet. It results in the development of the cracks in house. The cracks thus formed are sometimes 15 to 20 cm wide and 2.5 to 4.5 m deep.

Note :- Normally as per IS 1893:2016, when the N value of the soil at a particular level is less than 10 in Zone III, IV or V and less than 15 in Zone II, high rise building on such soils should be avoided or pile foundation or adequate soil stabilization should be done

2. If the thickness of black cotton soil strata is not more than 1200 mm. it is advisable to remove it completely.

Type of Foundation is used in black cotton soil :-

- Spread Footings and Wall Footings on Black Cotton Soil

- Under Reamed Piles on Black Cotton Soil

- Mat Foundation on Black Cotton Soil

- Special foundation

Spread Footings and Wall Footings on Black Cotton Soil :-

Spread footings and wall footings are used where a layer of good soil (soil which is capable of supporting the load of the building or soil which has the sufficient load bearing capacity) is within 2 m to 3 m from the natural ground surface in Zone IV .

Under Reamed Piles on Black Cotton Soil :-

Under-reamed piles are bored concrete piles having one or more bulbs or reams formed by enlarging the bases of the boreholes by an under-reaming tool. An under reamed pile is a pile of shallow depth (1 to 6 m) having one or more bulb at its lower end.

Due to the additional bearing and anchorage obtained from the bulbs, these piles provide economical and safe foundation in Black Cotton and other expansive soils, in filled-up soil and other soils of poor bearing overlying strata.

Mat Foundation on Black Cotton Soil :-

The mat foundation is suitable for black cotton/expansive soils whose bearing capacity is less for suitability of spread footings and wall footings.

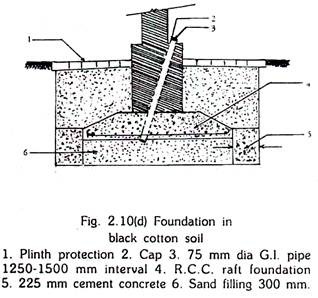

Special foundation with constant watch and sand filling arrangement

The foundation trenches are made 1500 to 1800 mm deep and width 450 mm wider than required. The extra width is filled up with cement concrete of equal width. The extra depth is filled up with sand 300 mm deep.

The bed is prepared by ramming, over which R.C.C. raft foundation is laid. 75 mm diameter G.I. pipe at 1,250 mm to 1,500 mm interval is installed from the plinth level extended up to the sand layer at the bottom. Due to change in season, cracks may occur in the Black Cotton soil. There may be loss of sand below the foundation

Removal of Black Cotton soil and filling with granular material :-

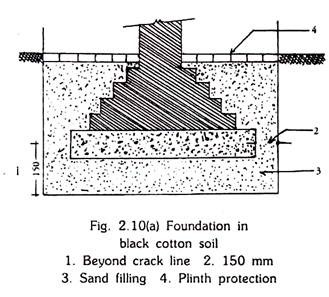

The depth at which the Black Cotton Soil is existing and its thickness can be ascertained by observation of cracks in the soil. If the depth is shallow, i.e., within 1200 mm, the soil may be excavated and removed.

The foundation trench may be made 150 mm more wide and depth 1500 mm below the depth at which the cracks cease.

Stabilization of Black Cotton Soil:

The quality of Black Cotton Soil can be improved by stabilizing it with lime.

The soil from the area is collected after removing the hard top-soil of depth about 70 to 100 mm. The soil collected is then pulverized. Fat lime (freshly slaked at site) is spread over the loose soil at the rate of 4 per cent of the dry weight of soil.

The soil is then compacted with 8 to 10 tonnes power roller resulting in a consolidated crust.