Bar Bending Schedule of Beam ( BBS )

What is Bar Bending Schedule ( BBS )

Bar Bending Schedule provides details of reinforcement cutting length, type of bends and bend length. It is Systematic tabular form or Simple form which provides the details like shape of the bar , dimension of bending of the bar etc.

BBS provides the reinforcement calculation for reinforced concrete beam

For Complete Example of Bar Bending Schedule Watch following video :-

Guidelines for preparation of BBS :-

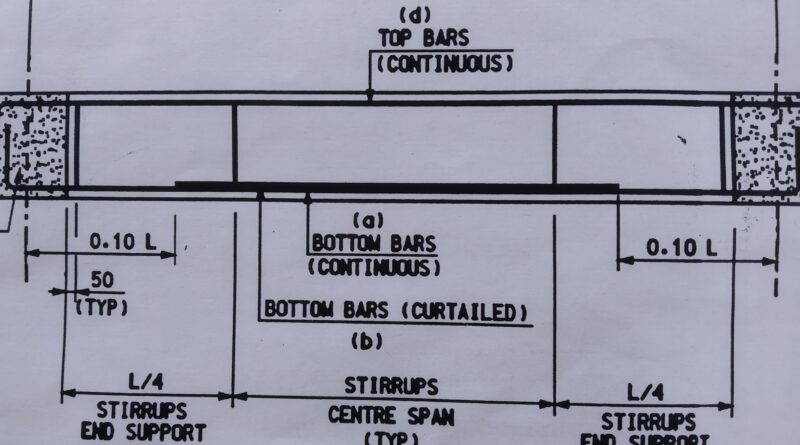

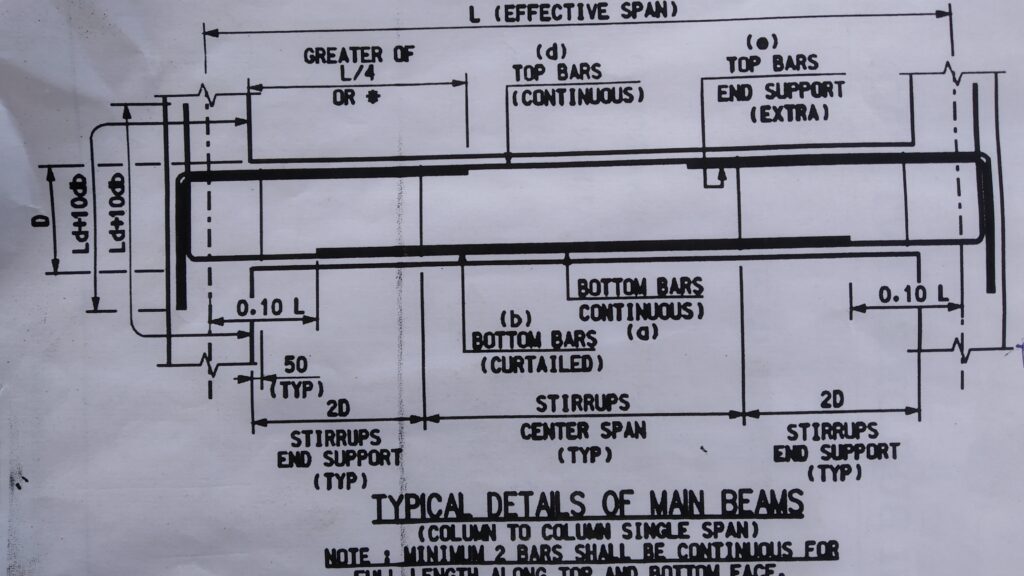

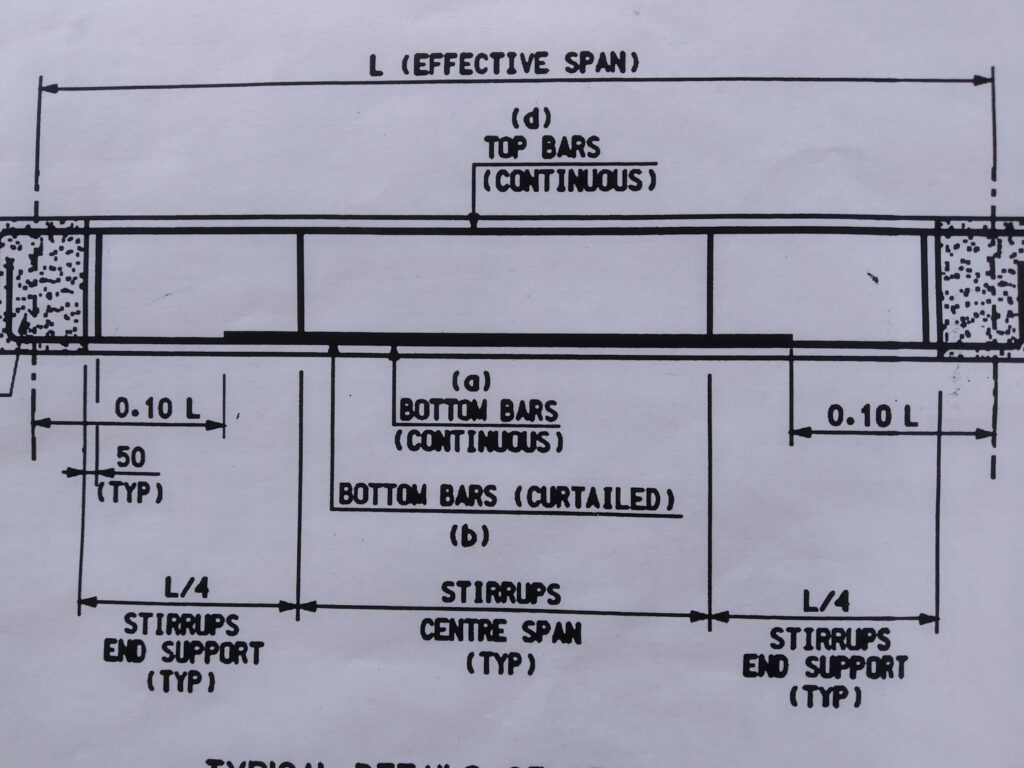

Curtail Bar ( Bottom Extra )

Curtailment is a theoretical point where some of the reinforcement is cut-off along the span of the beam where the bending moment reduces, given that the remaining reinforcement will be able to support the reduced bending moment.

The extra bar provided with main bar of bottom reinforcement in the center of the beam to resist Bending moment

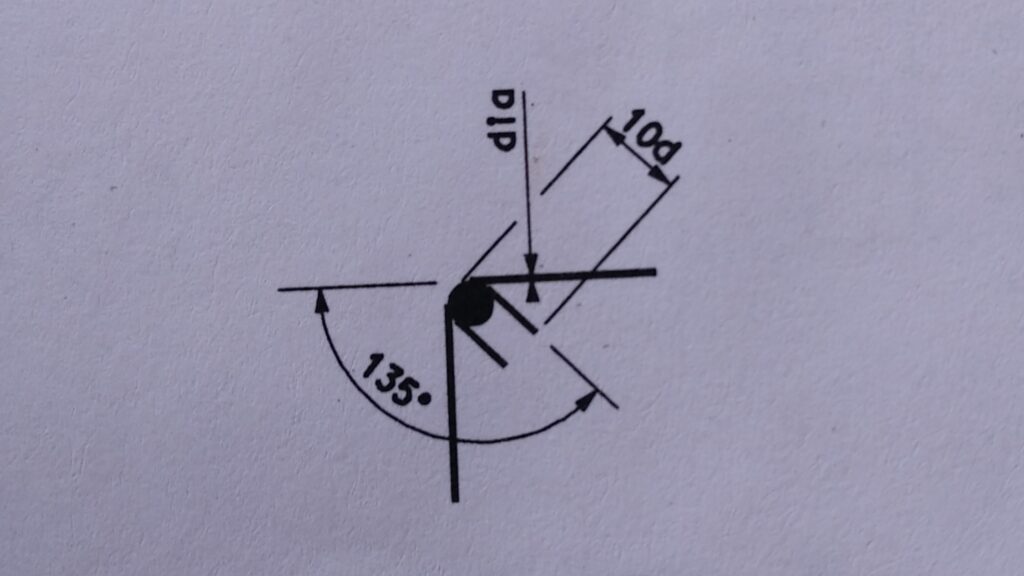

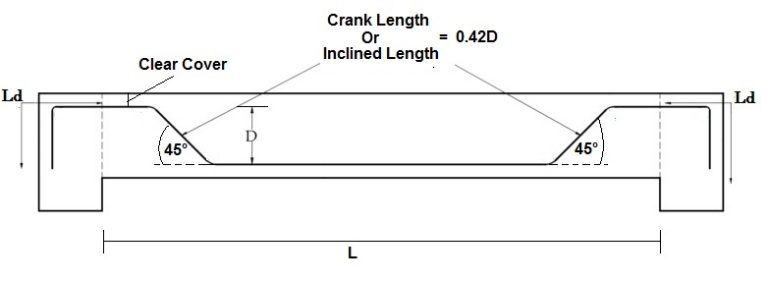

HOOK LENGTH:

The hook is the extra length left at the 4th corner of a stirrup so that the stirrup retains its shape

We generally consider length of hook = 10 D (for bars having diameter greater than or equals to 8 mm)

d = Diameter of stirrup

Is code recommends,

Minimum hook length = 75mm

Deduction for Elongation

135 Degree – 3d

90 degree = 2 d

45 Degree – 1d

Example :-

The total length of stirrups = Total length of the bar + 2 x hook length (for two hooks)

= L + 2 x 10 d -Deduction

= L + 20 d – Deduction

Where L = length of the bar for stirrup.

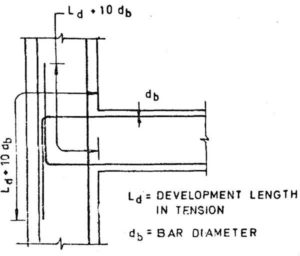

DEVELOPMENT LENGTH:

The development length can be characterized as the length of the bar required for transferring the stress into the concrete. The development length Ld of a bar is calculated as following

Where d = diameter of the bar.

σs = stress in the bar at the section considered as design load.

τbd = Design bond stress.

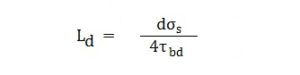

LAP LENGTH:

Lap length is one of the important term in the reinforcement. This is usually confused with another important term called development length and anchorage length.

Lapping can be defined as the overlapping of two bars side by side to up to the design length .

Lap length for tension members = 40 d

Lap length for compression members = 50 d.

where, d = Diameter of bars.

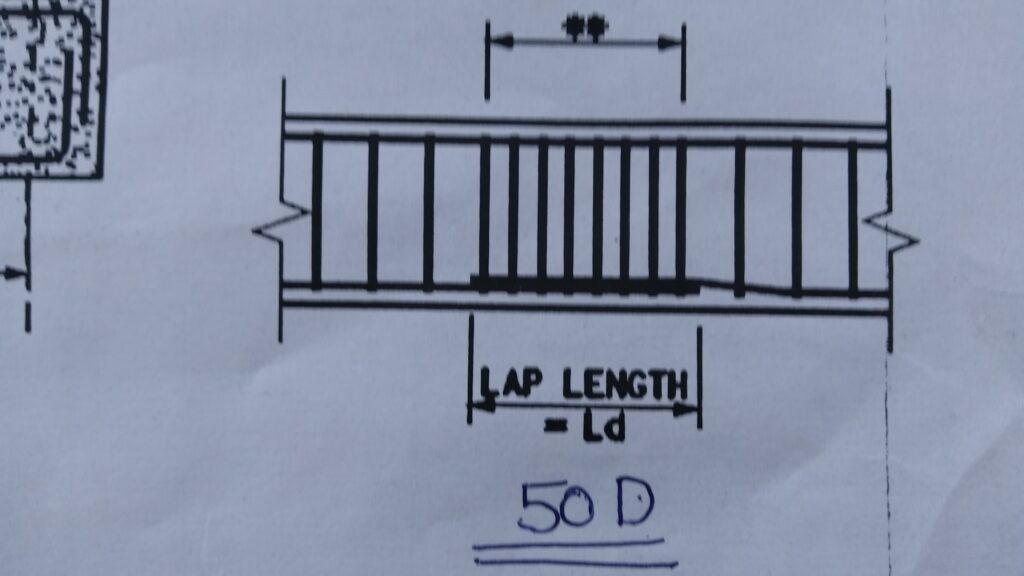

CRANK LENGTH:

Bars are bent near the support at an angle of 45°. The angle of bend may also be 30° in shallow beams. The purpose of bend near the support is firstly to resist the negative bending moment which occurs in the region of the support and secondly to resist the shear force which is greater at the support.

Crank bars are mostly provided in beams and slabs :-

Formula for calculation of Crank Length = 0.42 D

Where D = Clear height of the bar = Thickness of slab – (Top cover + Bottom cover) – Diameter of the bar