Concrete Slump Test acc. Latest IS Code 1199 – 2018 (Part-2)

The concrete slump (IS 1199 latest) test is done to check the workability of concrete and the consistency of fresh concrete. This test plays a very large role for concrete, it shows how much water has been added to the concrete or the amount of water in the concrete. This test is mostly done at the construction site.

Equipment

what apparatus is needed.

1.The first is Mould. Technically this type of mould is called Hollow Frustum. Which should be of metal and its thickness should be 1.6 mm.

2. Dimension, the diameter of its base should be 200 mm, diameter of top opening should be 100 mm and height should be 300 mm.

3 .Tolerance is allowed in this dimension. So the answer is (+/- 2) mm. Means suppose, height should be 300 mm in actual, but yours is 2 mm more, that is 302 mm, or 2 mm less, that is 298 mm, then according to IS code it will work. Acc. clause 4.3.2.1 of IS code 1199 – 2018 Part-2.

4. Tamping rod. With the help of which we will compact the concrete. Its cross section should be circular and its diameter should be 16 mm & length, should be of 600 mm . The tolerance for its diameter is, as per IS code, (+/- 1) mm. . And the tolerance for its length is, as per IS code, (+/- 5) mm.

5. Scale is needed to measure the slump value. Need a Rigid, Non absorbent plate with flat base. After that, a Shovel, a Concrete mixing tray which should be flat base and non absorbent. Along with this, there should also be a scoop and a stop watch.

Procedure concrete slump cone test (IS 1199 latest)

The composite sample should be collected different part of batch and not less than 0.02 cubic meters. The sample is used when the continuous mixtures are used.

First

First of all, you have to wipe Mould, Base plate, and mixing tray thoroughly. Keep in mind that there should not be any water etc. anywhere. Means that it should not be wet. Keep this in mind. Along with this, where the base plate and mold are kept, they should be vibration and shock free. so that it does not move.

Second

After that, start putting the concrete sample inside the mould and start tamping it with a tamping rod. Remember, you have to pour concrete in total 3 layers. That is, every layer will be of 100 mm. fill concrete in 3 layers, and tamping each layer 25 times. Tamping has to be done in such a way that your tamping rod can go to the next layer. That is, if you are tamping the 2nd layer, then the tamping rod should go in the first layer. Similarly, when tamping the 3rd layer, the tamping rod should go to the 2nd layer.

And each layer has to be tamped 25 times. { According to the new IS code, now concrete has to be filled in 3 layers. }

Third

In this way, after compacting the concrete well, the mold has to be filled up, till the top. After properly filling the top layer, the tamping rod has to be rolled over it. So that whatever extra concrete sample is removed from the top, it becomes a plane and uniform layer.

Fourth

Now you have to raise the mould vertically by holding both the handles provided in the mould. Remember, you do not have to apply any lateral or torsional force, that is, neither do you have to apply any horizontal force nor do you have to lift the mold by rotating it. Pull vertically upwards. And while doing this pull, you have to keep the stop watch on.

You have to complete this pull in 3 to 7 seconds. Actual time to pull is as per IS code, 5 seconds. Tolerance is (+/- 2) second. Along with this, you also have to keep in mind that, from concrete sample placing in Mould, to mould lifting, this process has to be completed within 180 seconds as per IS code. For reference, you can see clause number 4.3.3 (m) of IS 1199-2018.

Fifth

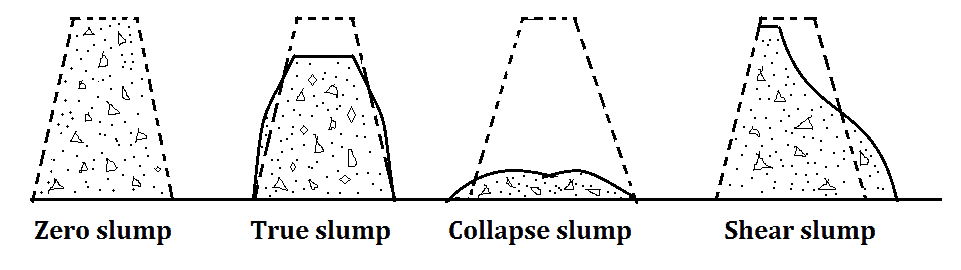

As soon as you lift the mould by vertical pull, you have to quickly check the slump value with the help of scale. Your slump value will be the measurement from the top of the mould to the top of the concrete. Its standard unit of measurement is mm.