How we construct structure under water

Making structure in the water is very big challenges for Engineers but there are many ways to construct structures under water are describe as following :

- Caisson

- Coffer dams

Caisson

A Caisson is a watertight structure used for retaining water in order to work on the foundations for bridges, piers, and other structures.

It is also called as pier foundation is a watertight retaining structure used as for foundations of bridges, piers, abutments in river and lake dock structure, foreshore protection etc .

It can be made up of wood, steel or reinforced concrete etc.

There are many types of caissons:

Box Caissons : Box caissons are put into place and the top of these boxes is open and filled with concrete, and may make up the foundation for other They are used for the construction of bridge pier.

These caissons must be anchored to allow them to remain in the proper position until they have been filled with concrete .

Open Caissons :

Open caissons are quite like box caissons but Open caissons do not have a bottom, and are driven into the soft ground to create a bottom.

There are two types of open caissons :

Top and bottom both open and open top-closed bottom. This type are not suitable for uses where there is a lot of hard soil or debris on the floor of the body of water .Open Caissons are used in the formation of the pier, deep manholes, pump stations.

Floating Caissons:

These type of caissons are prefabricating boxes filled with concrete mainly used in the construction of docks and harbors.

In certain cities and even countries the demand for land and space is rapidly exceeding the supply. Maritime centers do not escape from this reality, the continuous expansion of commercial maritime traffic and activities in seaports due to increases in international trading has generated an increased demand for an effective use of ports and harbors. Construction activities have been oriented to the expansion of existing facilities

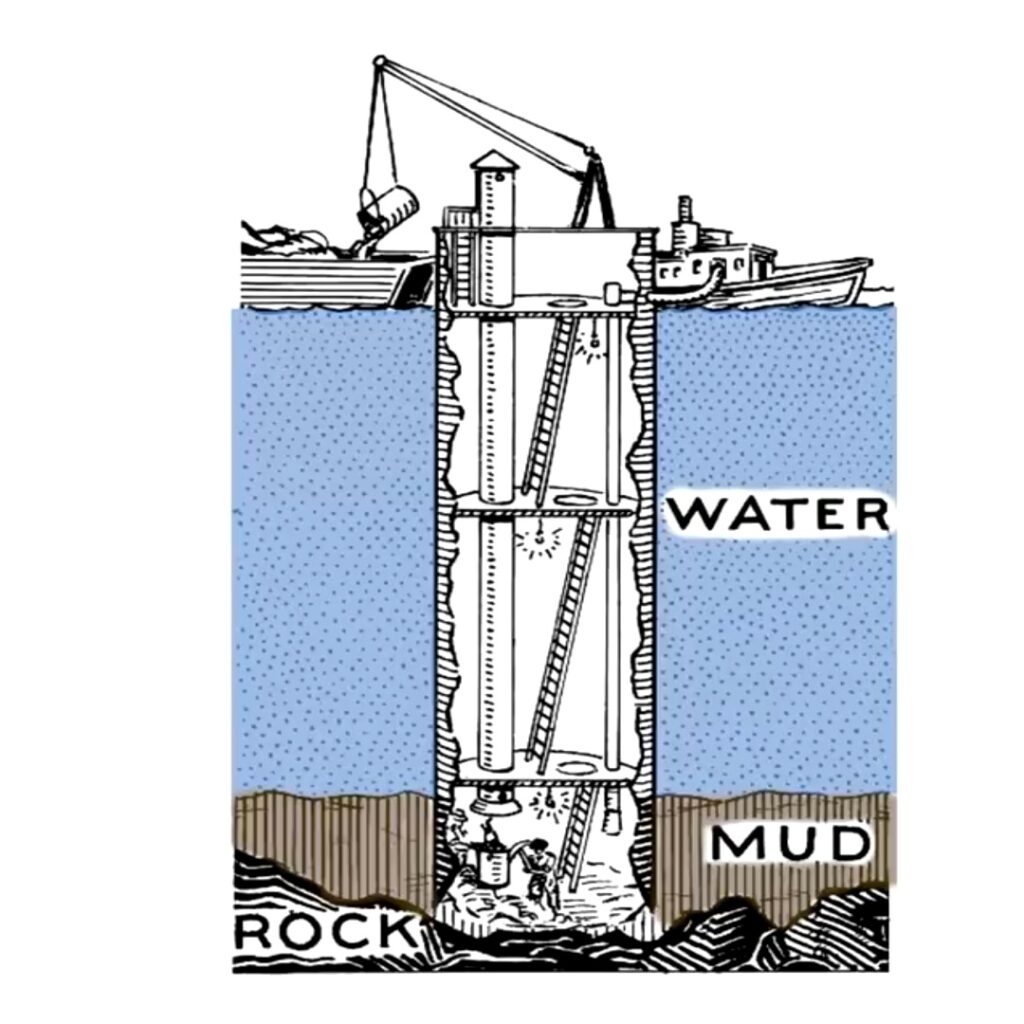

Pneumatic Caissons :

This type of caisson is closed at top and open (during construction) at the bottom. The water is excluded from the caisson chamber by means of compressed air.

Watertight or Box caissons which are used in underwater construction are known as pneumatic caissons.

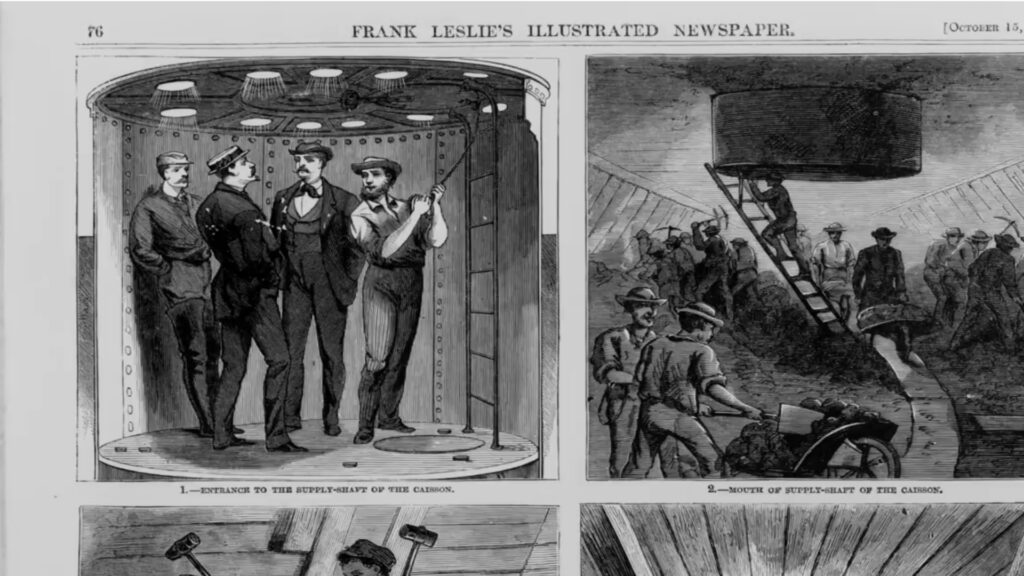

work Procedure in Pneumatic Caissons

In order that the workmen may carry out excavation work underneath the caisson and the water may not find its way inside from below, the pressure of the compressed air in the shaft is kept just higher than that of the water at that depth.

Each caisson has two air locks. Through one air lock workmen go down for working while through the other excavated material is taken out.

An air lock essentially consists of a steel chamber having two air-tight doors. One door of this chamber serves as an entry for men and material from outside into the steel chamber and the other door leads to the air shaft.

When a workman enters the airlock from outside, the pressure inside the airlock is the same as that of outside atmosphere. Thereafter the outside door is closed and the pressure inside the airlock is raised slowly.

When the pressure inside the airlock becomes equal to the pressure in the caisson, the door of the airlock which leads to the air shaft is opened and the workman goes down the air-shaft with the help of a ladder installed therein.

Exactly reverse procedure is followed when the workman comes out of the caisson. Air-shaft provides means of access for the worker from airlock down to the working chamber.

Compressed Air Caissons:

This type uses the power of compressed air to create a dry environment which is more adequate for the laying of concrete.

Excavated Caissons:

These kinds of caisson are used to excavate. Cylindrical shaped, these caissons are filled with concrete.

Construction Process

Following steps could be followed to build a caisson.

why we use Caisson

Followings are the suitable conditions for caisson foundation:

- When the depth of water level in the river and sea is high.

- When the soil is so hard and big debris which obstruct penetration of piles. .

- When the depth of water level in the river and sea is high.

- When the large lateral load is very high on foundation

Coffer dams

A cofferdam is a structure that retains water and soil that allows the enclosed area to be pumped out and excavated the area dry

Cofferdams are commonly used for construction of bridge piers and other support structures built within water.

Cofferdams are not permanent structure, and are typically employed to perform repairs or maintenance on the structure. Cofferdams may be used in new construction as well.

There are various types of cofferdams :

Earthen Cofferdamm

Earthen dams are constructed at the place where the height of the water is less say 3 metre and the current velocity is low.

Earth embankments are constructed around the area to be dewatered. The earth coffer dams are built of local soils, preferably fine sand.

These usually have a clay core or a vertically driven sheet piling in the middle. The upstream slope of the bank is covered with a rip rap.

The water collected is pumped out of the excavation. The embankment should be provided with a minimum free board of 1 m to prevent over topping by waves.

Rockfill Cofferdam

Rock fill coffer dams made of rock fill are sometimes used to enclose the site to be de watered. The height of the dam is can be up to 3 m.

The slope can be maintained at 1:1.5 to 1:125. The slope on the water side is pitched so as to protect dam from wave action.

These are permeable and are usually provided with an impervious membrane of soil to reduce seepage.

The crest and the upper part of the impervious membrane are provided with rip rap to provide protection against wave action.

Braced Cofferdam

They are formed from a single wall of sheet piles that is driven into the ground to form a “box” around the excavation.

The sheet piles are then braced on the inside and the interior is de watered. It is primarily used for bridge piers in shallow water ( 9 to 12 m depth).

Single-Walled Cofferdam

This type of cofferdam is preferred when the depth of the water is more than 6m and area of construction is less. Usually this is used in construction of bridges.

Double-Walled Cofferdam

They are cofferdams comprising two parallel rows of sheet piles driven into the ground and connected together by a system of tie rods at one or more levels.

The space between the walls is generally filled with granular material such as sand, gravel or broken rock.

Cellular Cofferdam

When the water layer is more than 20 m, this type of coffer dam is used. Cellular cofferdam is made by driving straight web steel sheet piles, arranged to form a series of interconnected cells.

The cells are constructed in various shapes and styles to suit the requirements of site. then these cells are filled with clay, sand or gravel to make them stable against the various forces to which they are likely to be subjected to.

Note :

Cellular cofferdams are used only in those circumstances where the excavation size precludes the use of cross-excavation bracing.

Greetings! This is my 1st comment here so I just wanted to give a quick shout out and say

I truly enjoy reading your articles. Can you recommend

any other blogs/websites/forums that deal with the same subjects?

Thanks for your time!

Hello, its fastidious article regarding media print, we

all be familiar with media is a fantastic source of facts.

It’s remarkable to visit this website and reading the views

of all mates about this piece of writing, while I am also eager of getting familiarity.